Wheel Services

Bicycle Wheel Services

- Hand-Built Custom Wheel – REAR: $250

- Hand-built Custom Wheel -FRONT disc brake: $250

- Hand-built Custom Wheel -FRONT rim brake: $175

Hand Built Wheels

Custom wheels are the foundation of Optimized Cycling Solutions.

Wheels have become one area of the bike where huge improvements in performance can be achieved. At OCS we work one on one with the client to design the wheels that make the most sense for that individual’s needs.

It starts with a discussion about the bike that the wheels will be mounted on. There are multiple compatibility considerations, so understanding a riders specific requirements helps us design wheels that perform remarkably well, but are also reliable in the real world.

Attention to detail

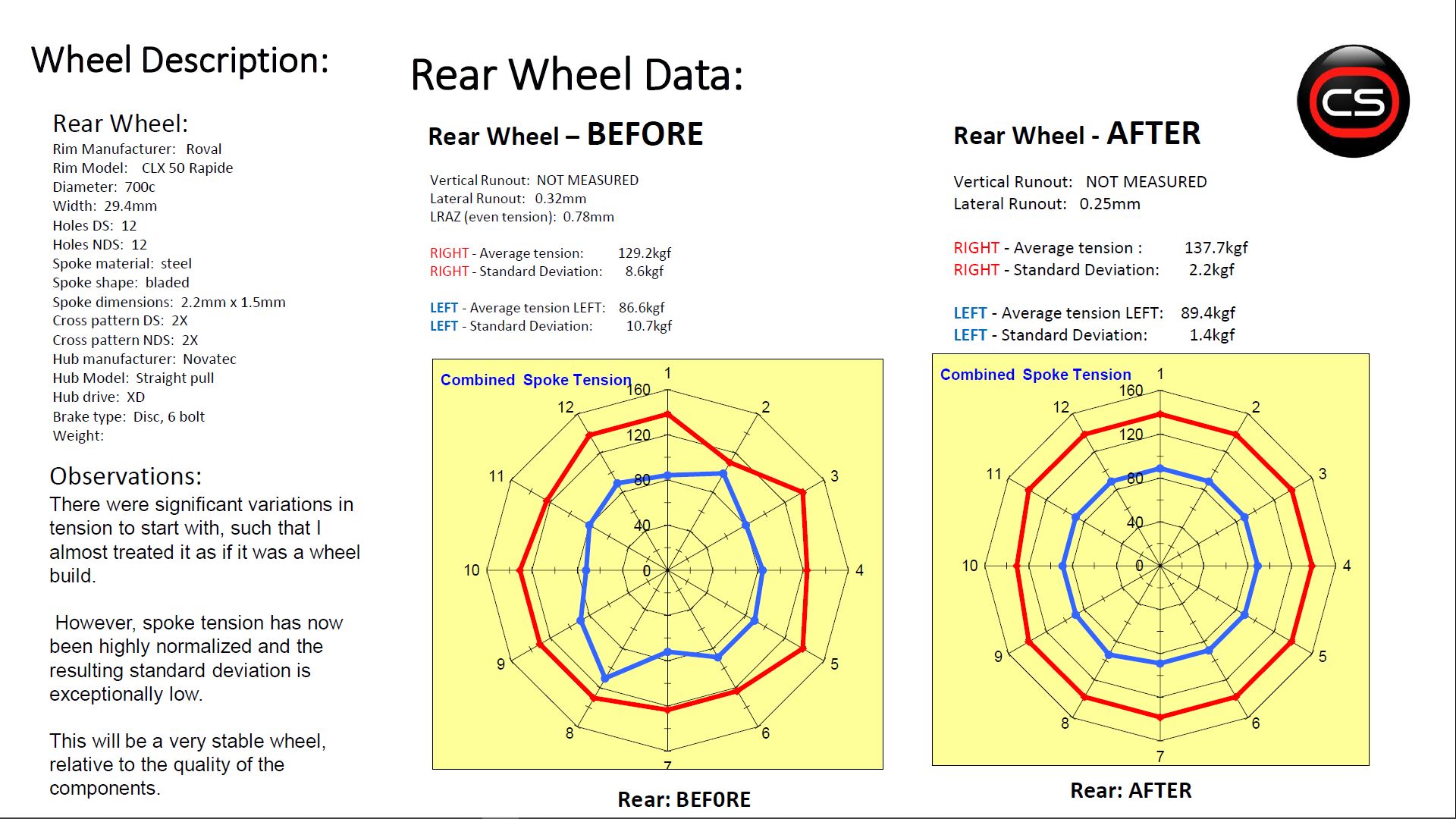

At OCS we utilize systems and technology that enable us to build wheels that are both very straight, but also possess exceptionally uniform spoke tension. It is a time-consuming process but is necessary to ensure that the wheels have the desired ride qualities and are also reliable. Our data driven process not only benefits our clients, but also our suppliers, as with ENVE Composites.

Lifetime truing and data tracking

The spoke tension and run out data are tracked throughout the life of the wheel (we take an additional reading whenever the wheel is in our shop for service). This allows us to observe the changes in the wheel throughout its service life and identify when it requires either service, replacement or a rebuild. Safety and performance are our primary objectives.

Wheel Optimization

Modern bicycle wheels utilize advanced materials, aerodynamic development, and improved mechanical systems, but if these various components are not mechanically optimized the resulting wheels will be less structurally sound, less reliable and a potential safely liability.

Common issues that we encounter, and resolve, are either too little spoke tension and/or uneven spoke tension. This can occur even on brand new pre-built wheels (some manufacturers are far better than others).

To address these various issues, the OCS Wheel Optimization Process includes:

- Measure Spoke Tension and Runout

- Map and analyze defects

- True Wheel

- Balance Spoke Tension

- Optimize Hub Adjustment

- Create Report with results

The resulting report characterizes the Before and After data for each wheel as well as observations regarding its overall health. It also provides us with benchmark data that we can refer to later.

New Wheel Validation

We sell prebuilt wheels from multiple brands including Campagnolo, HED and others.

All prebuilt wheels we sell go through the same inspection, measurement, and Optimization process as our signature hand-built wheels.

This is included at no extra charge and allows our clients to benefit from OCS processes on new wheels they purchase from us.