OPTIMIZATION

OPTIMIZATION and Report

The OPTIMIZATION Process is one of the absolute best ways for us to begin a client and service provider relationship with a new rider.

Essentially, an OPTIMIZATION is a full overhaul of the bicycle with a data package that documents the physical condition of the bike, as well as any potential issues.

INCLUDED PROCESSES

- Remove all parts from bicycle

- Clean, inspect, photograph, and lubricate all components.

- Wax all components where applicable

- Clean, inspect, photograph and wax frame.

- Check frame alignment

- Adjust rear derailleur hanger alignment if possible and/or necessary

- Install new cables & housings for brakes & derailleurs (parts not included)

- Update firmware on electronic drive trains

- Bleed brakes, if hydraulic

- Perform full OCS WHEEL OPTIMIZATION process on both wheels

- Create diagram of the bike using BikeCAD Pro software

- Identify and document all potential issues with the bike.

OPTIMIZATION REPORT

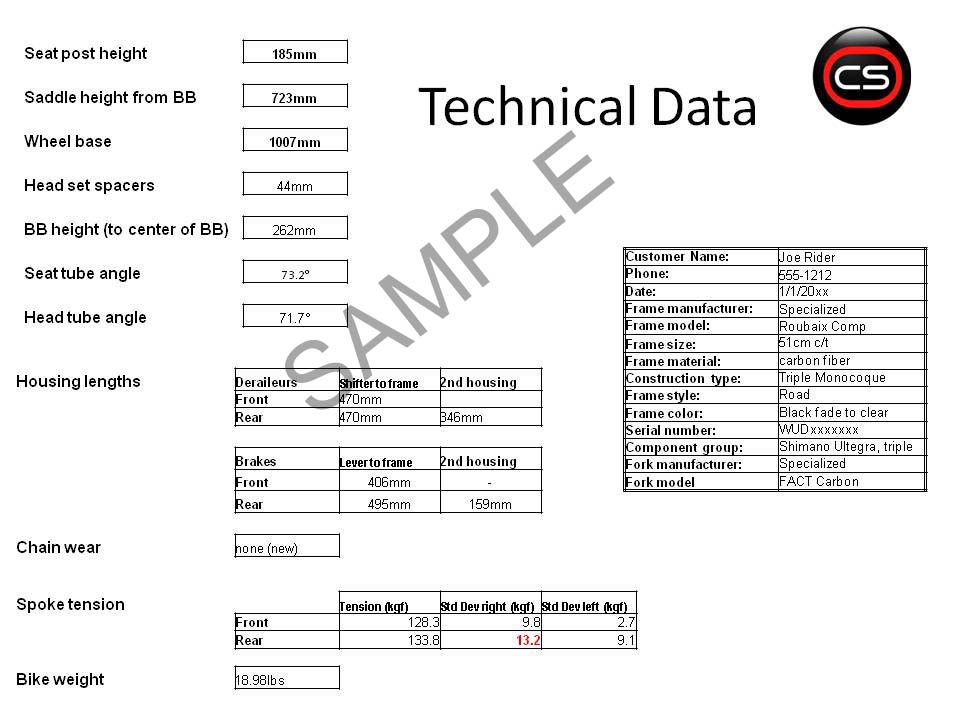

- Technical data including weight, cable housing lengths, components, and many others

- Full diagram of the bike including a rendering of the rider

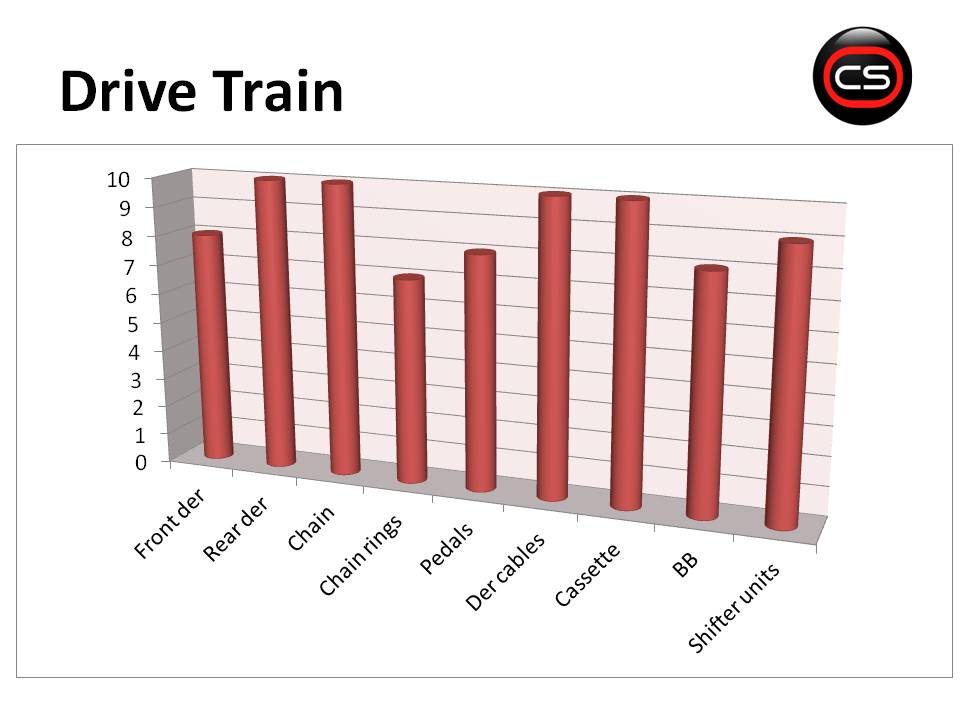

- Evaluation of all components and systems on the bike

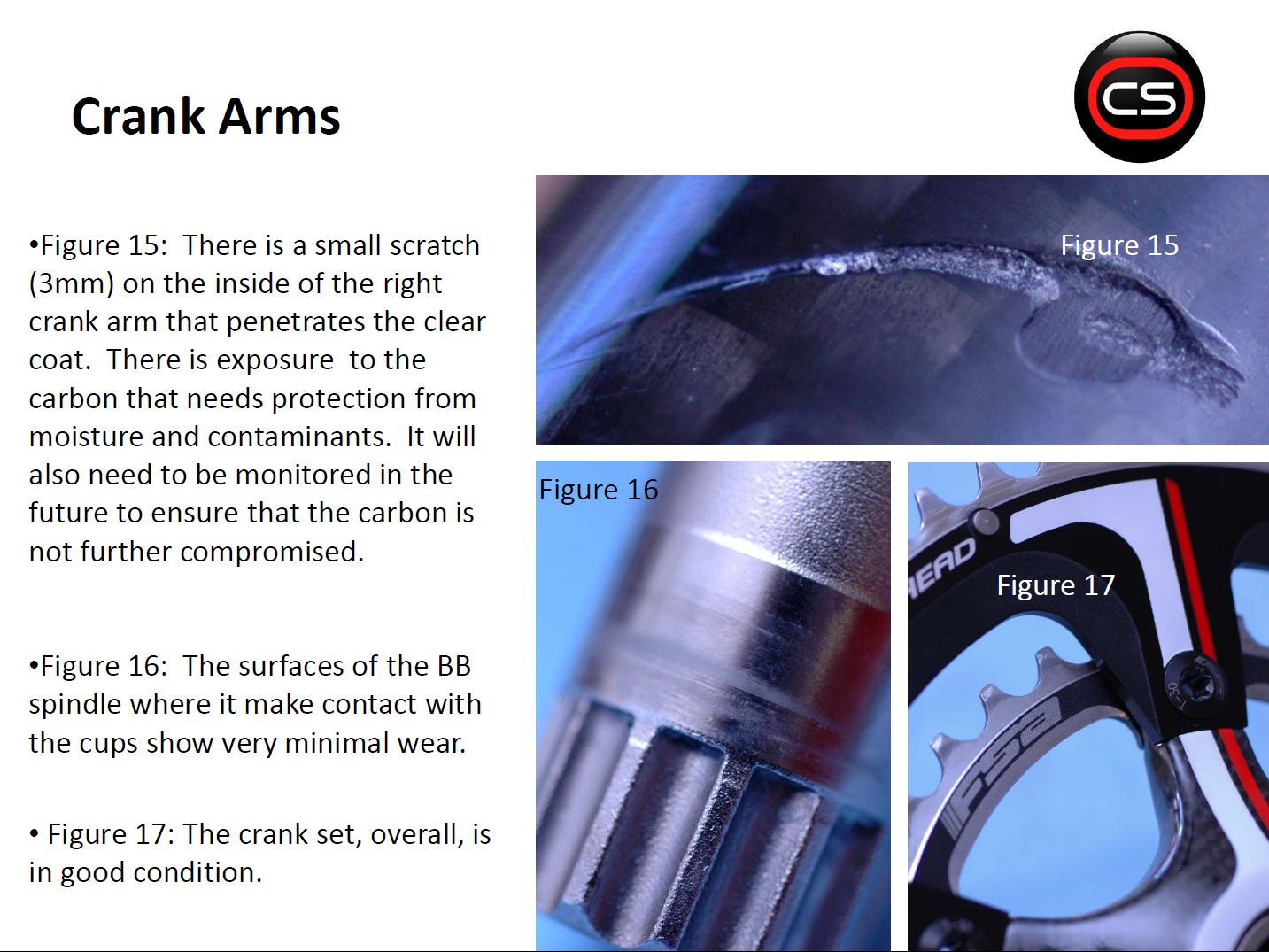

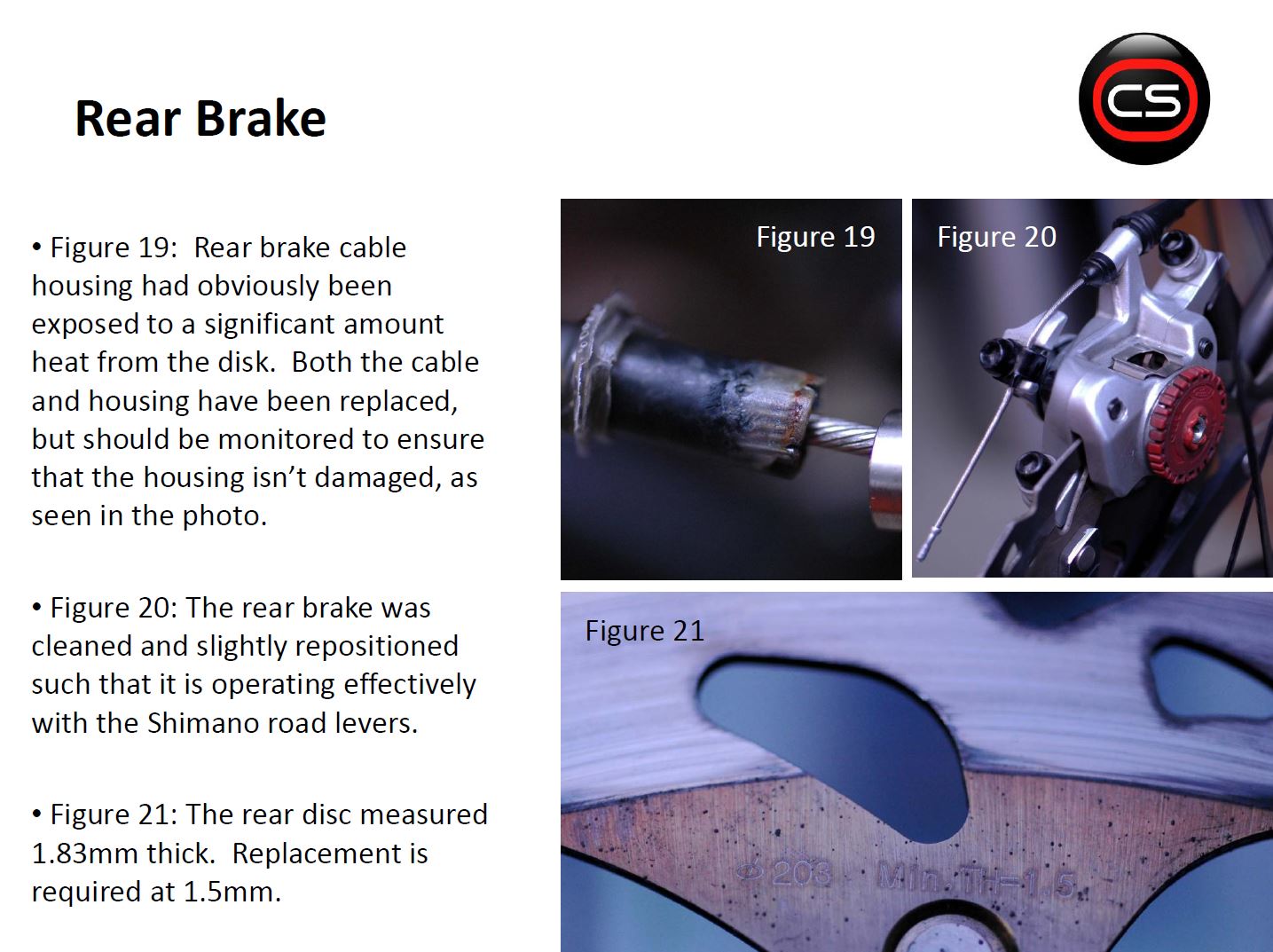

- Photographic and/or measurement data on areas of concern

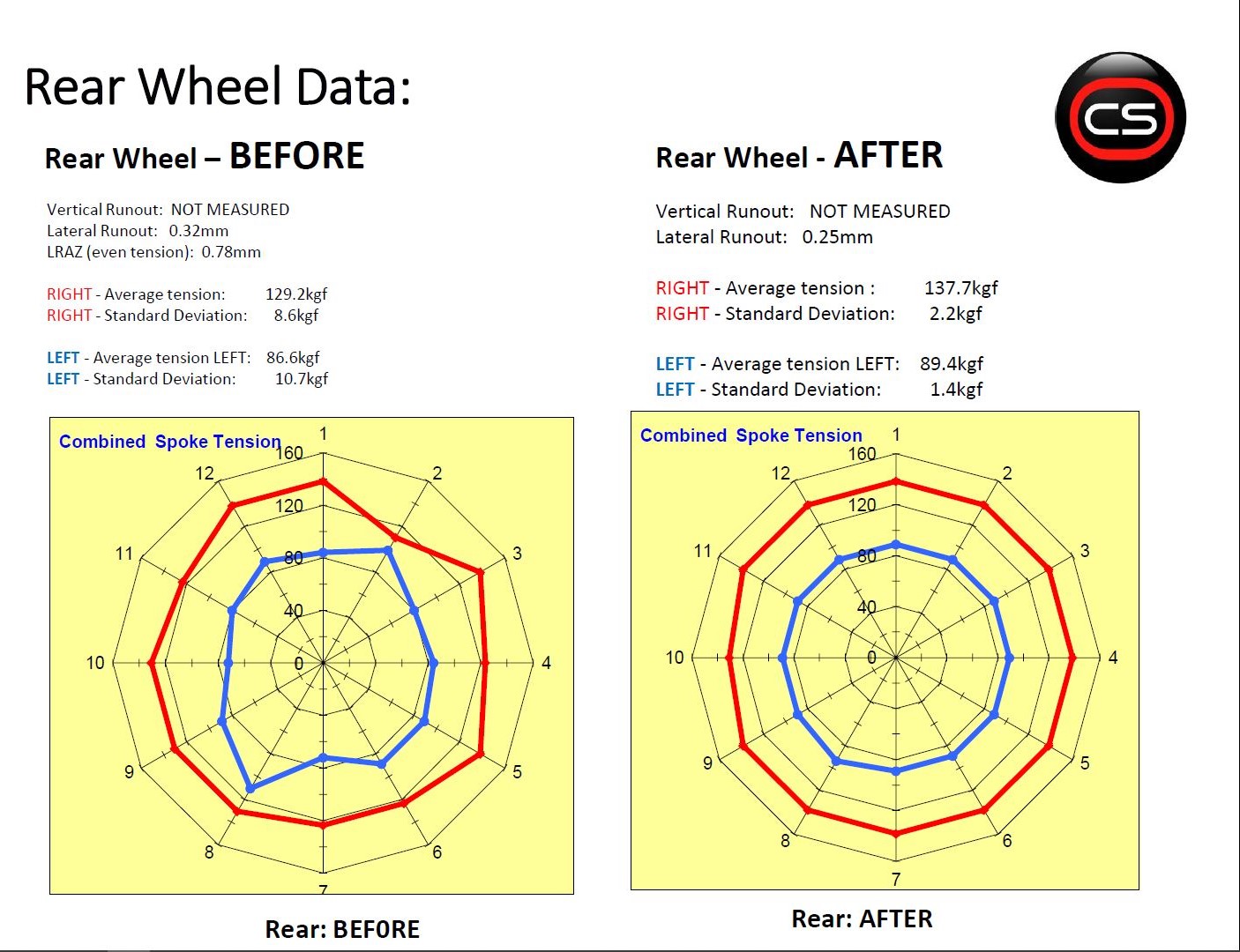

- Spoke tension data for both wheels, before and after Wheel Optimization process

- Summary of overall bike health

Recommendations regarding service intervals and upgrades

ADAPTABILITY

Our business model at OCS is such that we only focus on the needs of a relatively small number of clients. This allows us to provide them with an unprecedented level of attention to detail regarding their specific needs.

- Understand their equipment sets, regardless of what style bike/s they own

- Become better acquainted with their morphology and injury history

- Utilize the available data and images to better understand their usage patterns and attrition rates.

- Fabricate tools when necessary, to complete the immediate job at hand and remain prepared to satisfy that client’s needs efficiently in the future.

Example: It took 35 minutes to fabricate a tool to release the main spring on Campagnolo front derailleurs.

The result is simply stunning for many of our clients when they go for that maiden voyage after an OPTIMIZATION.

SUMMARY

Every Optimization Report is unique, just like every rider. These reports are tailored to the specific needs of the rider, depending on the bicycle type as well as being presented in a way that is useful and accessible to the client.

For example, the needs of a client that rides 10,000 miles a year on a road bike will be different than someone that rides 500 hours per year on an All-Mountain MTB. Not only will their mechanical service protocols be different, but they may also have vastly different needs regarding the way that data is presented.

Road riders may be more focused on efficiency, whereas a serious MTB rider will likely be more concerned with brake attrition, suspension setup and tire selection.

We work one-on-one with clients to find out what their goals are, as well as the things they would like to improve about their current equipment solutions.