OPTIMIZED BICYCLES

In 2014 Mark had a unique opportunity to launch his brand of custom carbon fiber bicycles called OPTIMIZED.

The supplier was a company in Northern Italy with whom he had worked in the past which provided him with a nearly unlimited number of options to satisfy the needs and desires of his clientele.

From tube diameter, to shape, carbon modulus, layup, geometry as well as bottom bracket shell, cable routing, headset diameter, and fork.

Custom paint further allows the client to create something in conjunction with Mark that is one of a kind, tailored to their specific needs and taste.

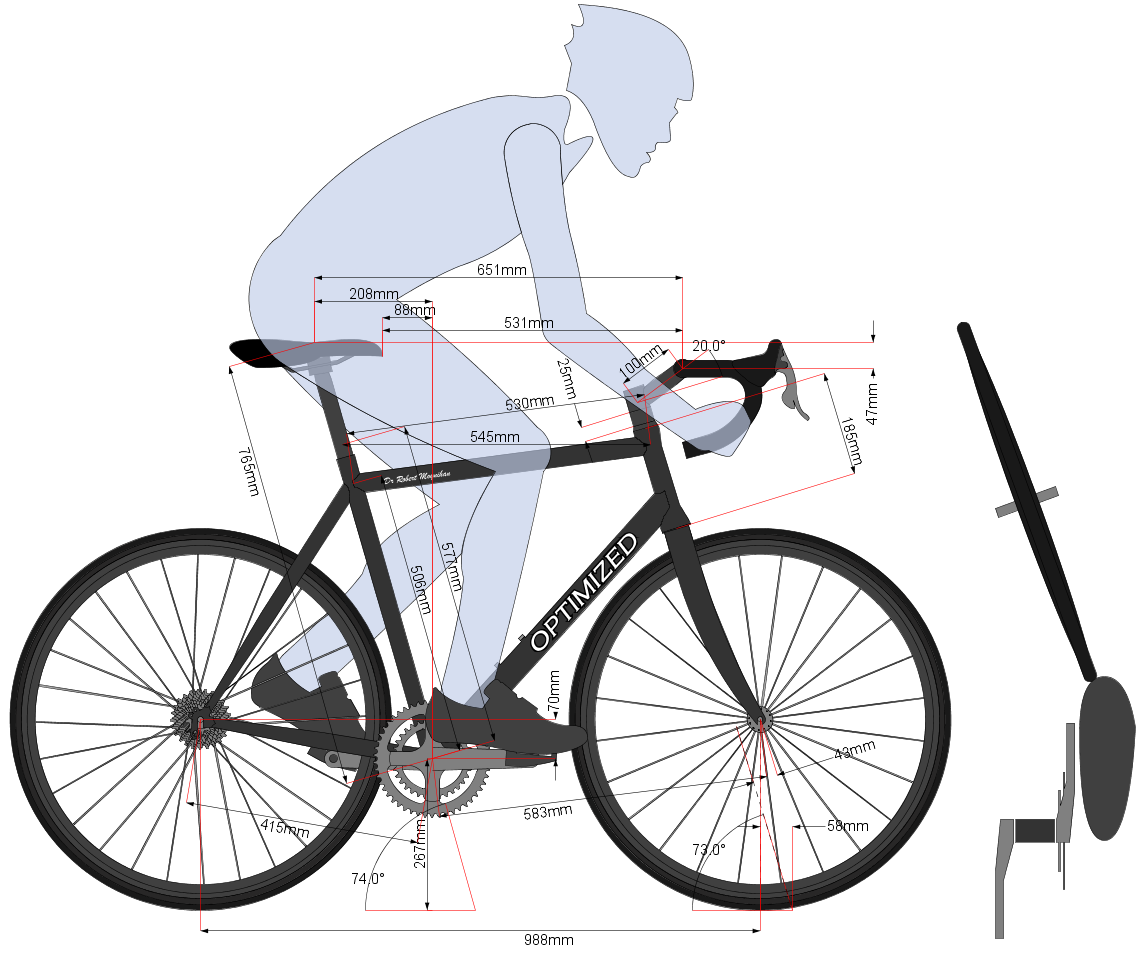

A primary consideration when designing and building a custom bike for a rider is to account for their physiological needs and injury history, more specifically.

In the case of my friend, Dr. Robert Moynihan, he had a condition that required him to adjust his current position on the bike, resulting in more spacers at the headset than I would normally run on a custom bike. However, importantly I allow him the flexibility of removing those spacers later as his condition improves. It is easier to shorten the steer tube of the fork than it is to shorten the head tube of the frame.

Another crucial opportunity with a custom bicycle, regardless of material, is that it allows a designer like Mark to accommodate the needs of riders with asymmetrical morphology. For example, most bicycles are built for men that have a long torso and short legs, relatively speaking. In the case of Andre, we were not only able to achieve his fit parameters but also choose tubing that was able to support a rider that is nearly 6 ft 3 and provide him with stability as well as comfort.

Once the frame design was complete Mark sat down with him and together, they designed the paint job. This is a wonderful option for people to truly create their “perfect bike”.

To create something so special that they simply can’t wait for the next time they get to throw their leg over that bike and ride. Everything else is waiting.

Using the OCS data-driven approach which amalgamates photos, measurement data, anecdotal observations, the detailed analysis of frame geometry and morphology, as well as detailed reports that provide us with the necessary information allow us to anticipate our clients’ service needs.

The OPTIMIZED brand did not last for long. That is the nature of business sometimes and even though it can be painful there are valuable lessons to be learned.

Everything that Mark has learned from the many custom bike factories and shops he’s worked with around the globe, goes into the next bike.

We have some remarkable suppliers now and will be announcing more in the future.

The OPTIMIZED brand of custom bicycles may emerge again someday, but until then we are very proud of our current lineup of bespoke frame builders.